Fabric End Cutters should also be maintained frequently when they are used, so as to delay the service life of the machine.

Routine maintenance of traditional Fabric End Cutters:

Routine maintenance of traditional Fabric End Cutters is the responsibility of the operator. The operator must know the structure of the equipment and follow the operation and maintenance procedures.

- Before the start of work (shift change or intermittent work), the main department of the machine should be inspected and lubricated.

- Use the equipment strictly in accordance with the equipment operation rules, pay attention to the operation status of the equipment, and deal with problems in time.

- Before the End of each shift, clean the work once, and apply lubricating oil to the friction surfaces and bright surfaces of Fabric End Cutters.

- Under the normal working condition of two shifts, Fabric End Cutters will conduct a comprehensive cleaning and inspection of the machine every two weeks.

- If the machine is put in use for a long time, all shining surfaces shall be wiped clean and coated with anti-rust oil, and the whole machine shall be covered with a plastic cover.

- Proper tools and unfair beating methods should not be used when disassembling and assembling the machine.

Automatic Fabric End Cutters with Factory Price, Cloth Lay Cutting Machines Manufacturer

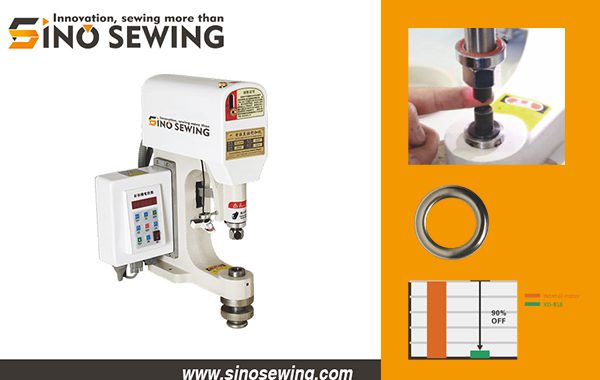

The Automatic Fabric Lay End Cutter produced by SINO is servo motor with long service life and simple operation and maintenance.

The following are the characteristics of Automatic Fabric End Cutters:

- Adopts innovative servo motor, brushless, and no spark in running. With brake function, which blade running is stopped after delay time, operating safer.

- Adopts servo drive motor, which keeps it start instantly, high efficiency, the rotate speed can reach fastest in one second, with flat and smooth cutting edge, no burrs.

- The power interface adopts magnetic socket, silver point contact, good conductivity, and longer service life.

- The wire is coated by polyurethane material, and flexible parts is with spring structure, more durable.

More about fabric end cutter, please keep on paying attention to our offical website: https://www.sinosewing.com/, or send email to us: sales@sinosewing.com