Description

Features of Model: SS-511-2

1) Double work stations, greatly improve work efficiency.

2) The Heat Press Transfer Machine adopts lever principle to increase the cylinder stroke, so that increase pressure in double, but saving 85% gas compares with traditional machine.

3) Adopt clamshell structure, the operating space is larger and easy to clean, operation and maintenance easier.

|

|

|

|

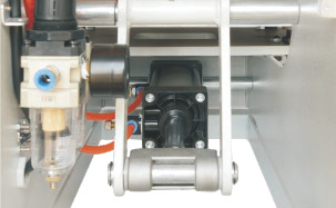

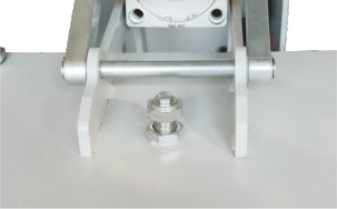

| Pressurization Cylinder | Displacement Cylinder | Pressure Adjusting Nut | Saving 85% Gas Consumption |

|---|

Technical Data Sheet of Model: SS-511-2

| Model | Plate Spec. (mm) | Voltage (v) | Atmospheric Pressure (kg/cm) | Power (w) | Pressure per CM² (g/cm) | Machine Pressure (kg) | G.W. (N.W.) (kg) | Size (cm) |

|---|---|---|---|---|---|---|---|---|

| SS-511-2 | 400*600 | 220 | 5 | 2800 | 420 | 1000 | 88 (79) | 650*700*850 |